The irreplaceability of PET sheets and rolls in the blister industry

The irreplaceability of PET (Polyethylene Terephthalate) sheets and rolls in the blister industry stems from their unique combination of properties and versatility, making them indispensable for a wide range of blister packaging applications. Here's why PET sheets and rolls are considered irreplaceable in the blister industry:

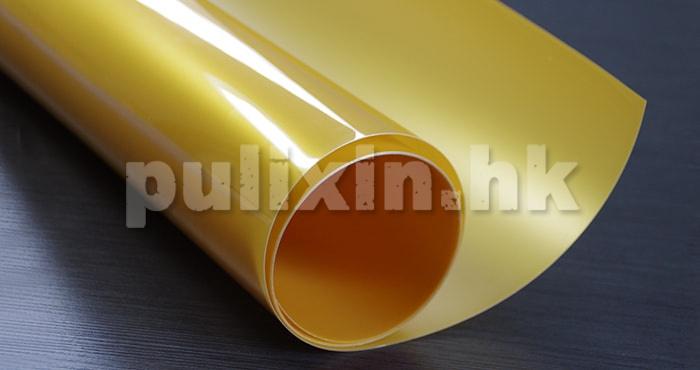

Clarity and Transparency: PET sheets offer exceptional clarity and transparency, allowing for clear visibility of the packaged products. This property is crucial in the blister industry, where product visibility is essential for consumer appeal and product recognition on retail shelves.

Formability: PET sheets exhibit excellent formability, enabling them to be thermoformed or molded into precise shapes and sizes to accommodate various products. This formability allows for the creation of custom-shaped blister cavities that securely hold products in place, enhancing product presentation and protection.

Durability: PET sheets are durable and resistant to punctures, tears, and impacts, providing reliable protection for blister-packaged products during handling, transportation, and storage. This durability ensures that the packaged products remain intact and undamaged throughout the distribution chain, reducing the risk of product spoilage or breakage.

Barrier Properties: PET sheets offer excellent barrier properties, including moisture barrier, oxygen barrier, and aroma barrier, which help protect blister-packaged products from environmental factors such as moisture, oxygen, light, and odors. This barrier protection helps extend the shelf life and maintain the quality of the packaged products, particularly sensitive items such as pharmaceuticals, medical devices, and electronics.

Sealability: PET sheets exhibit good sealability, allowing for reliable and secure seals between the blister and the backing material (e.g., paperboard, foil, or film). These seals prevent tampering, contamination, and pilferage, ensuring the integrity and safety of the packaged products.

Compatibility: PET sheets are compatible with a wide range of printing and labeling techniques, including offset printing, flexographic printing, digital printing, and thermal transfer printing. This compatibility allows for the customization and branding of blister packaging with product information, logos, graphics, and barcodes, enhancing the visibility and marketability of the packaged products.

Recyclability: PET sheets are fully recyclable and can be collected, sorted, and processed into recycled PET (rPET) for use in the production of new packaging materials. This recyclability promotes sustainability and environmental stewardship in the blister industry, reducing reliance on virgin materials and minimizing waste sent to landfills.

In conclusion, the irreplaceability of PET sheets and rolls in the blister industry is attributed to their clarity, formability, durability, barrier properties, sealability, compatibility, and recyclability. As a result, PET remains the preferred material for blister packaging applications, offering manufacturers reliable, efficient, and cost-effective solutions for packaging a wide range of consumer and industrial products.