Transparent Rigid PET Sheet for Blister Packing

Parameters Guide

| Category: | Thermoforming APET Plastic Sheet Roll |

| Process: | Co-Extrusion Squeeze Out |

| Thickness: | 0.18mm-2mm |

| Width: | 300mm-850mm |

| Color: | Clear / Transparent / Black / White / Customize Color |

| Shape&Weight: | Up to 150kg/Roll |

| Certificate: | SGS, ISO9001,ISO14001 |

| Temperature: | -30℃-120℃ |

Product Description

Description

PET plastic sheet (polyethylene terephthalate) is a common thermoplastic with high stability, excellent mechanical strength and good creep resistance. PET is chemically resistant, has very low hygroscopicity and is a good electrical insulator.

PET material is economical and versatile, and is currently one of the most productive plastics in the world. Through different additives, it can show different physical and mechanical properties, suitable for different purposes, such as conductive PET plastic sheets can be used for blister packaging of electronic products. Adding appropriate amount of plasticizer can be made into hard, soft and transparent products.

PET plasstic sheet

PET plastic roll

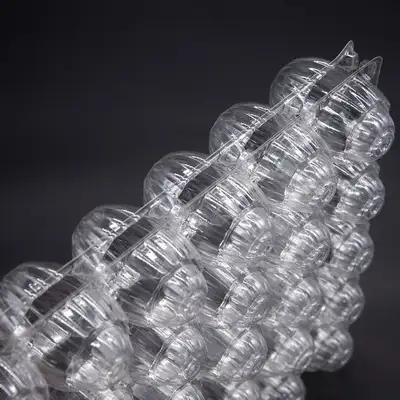

What is blister packaging? Blister packaging is formed by heating a piece of plastic sheet and cooling it, and different molds can form different styles of blister packaging. PET plastic sheets can be used in thermoforming to make medical packaging, food packaging, clam shell packaging, blister packaging, domes, etc.

The PET plastic sheet roll series includes APET, PETG, GAG, which is a new type of material with rapid development. It has the advantages of excellent comprehensive properties, high transparency, good strength and easy post-processing. Due to its good strength, products of the same thickness have significantly better protection effects than PVC sheets. If the same strength is compared, a thinner PET plastic sheet can be used instead of the PVC sheet. Therefore, although the price of PET sheet is higher, the actual cost increase is not large, and more importantly, the PET plastic sheet is more crystal clear.

PET sheet characteristics

• High chemical stability, good fire resistance and ultra-transparency.

• High UV stability, good mechanical properties, high hardness and strength.

• Good aging resistance, good self-extinguishing and reliable insulation.

• Waterproof, smooth surface, not easy to deform.

• Anti-static, anti-UV, anti-stick

Why choose PULIXIN?

About us

PULIXIN Packaging Materials (Shanghai) Co., Ltd. is an excellent professional PETG plastic sheet manufacturer in China. We produce all kinds of PETG sheets, especially antistatic and coated conductive sheets.

PULIXIN owns 39 new product patents, covers an area of more than 6,000 square meters, and can produce at least 100 tons of transparent thermoforming polyethylene terephthalate sheets per day, meeting your large-scale demand or urgent order requirements in peak seasons.

Our advantages

1. Strict QC team,quality satisfaction rate meets 99%.

2. More than 10 set advanced automated equipments,meet high end quality requirement.

3. Free design service and fast sample lead time in 3 day.

WHY CHOOSE USMore >>

Click to see workshop, equipment, certificated qualification and advantage strength of Pulixin(HK)- A professional PP PS PET sheet manufacturer

Not Trader But Factories

Up to 100% Virgin Material

Experience, Certification & Patent

High-standard Quality Inspection

Multiple Advanced Lines 7-12 Days Delivery

Safe Packing For International Transport

Product Application

Transparent Rigid PET Sheet for Blister Packing normally has a wide range of useage like consumer product packaging, electronic tray, fresh food Crisper,cosmetic packaging, Medical device blister packaging.