Thermoformed HIPS Plastic Roll

Brief introduction of Thermoformed HIPS Plastic Roll

Thermoformed HIPS plastic roll is a plastic sheet made of high impact polystyrene with good thermoforming properties and can be processed into products of various shapes.

It has the advantages of high cost performance, good processing performance, forming performance and dimensional stability, as well as non-toxicity, odorlessness and recyclability.

HIPS plastic sheet is widely used in food packaging, electronic product packaging, toys, stationery, construction and other fields.

Product Advantage of Thermoformed HIPS Plastic Roll

High impact resistance: It has good impact resistance and bending resistance, and can withstand large loads.

1. High toughness: It has good toughness and is not easy to break.

2. Heat resistance: It has good heat resistance and can be used for thermoforming.

3. Good processing performance: Thermoformed HIPS plastic roll can be processed by a variety of processing methods, such as thermoforming, injection molding, extrusion, etc.

4. Good formability: Thermoformed HIPS plastic roll can be formed into various complex shapes.

5. Good dimensional stability: HIPS plastic roll has good dimensional stability and is not easy to deform.

6. Non-toxic and odorless: HIPS plastic roll is non-toxic and odorless, and can be used for food and medical packaging.

7. Environmental protection: It is a recyclable material that meets environmental protection requirements.

8. High cost performance: The price of Thermoformed HIPS plastic roll is relatively low and cost performance is high.

Product Application of Thermoformed HIPS Plastic Roll

Thermoformed HIPS plastic roll have a wide range of applications and can be used in food packaging, pharmaceutical packaging, electronic product packaging, cosmetic packaging, industrial product packaging and other fields. The specific applications are as follows:

1. Food packaging: Thermoformed HIPS plastic rolls are often used to make food packaging boxes, trays, plastic wrap, etc.

2. Pharmaceutical packaging: Thermoformed HIPS plastic rolls are often used to make pharmaceutical packaging boxes, bottle caps, PTP trays, etc.

3. Electronic product packaging: Thermoformed HIPS plastic rolls are often used to make electronic product packaging boxes, trays, anti-static bags, etc.

4. Cosmetic packaging: Thermoformed HIPS plastic rolls are often used to make cosmetic bottle caps, pipes, packaging boxes, etc.

5. Industrial product packaging: Thermoformed HIPS plastic rolls are often used to make industrial parts, mechanical parts, electrical components, etc. packaging.

Categories and Properties of Thermoformed HIPS Plastic Rolls

| Category | Properties |

| Conductive polystyrene sheet | Surface resistance can reach 1O^4~10^6. |

| Semi-conductive polystyrene sheet | Surface resistance can reach 10^6~10^9. |

| Ordinary anti-static polystyrene sheet | Surface resistance can reach 10^9~10^12. |

| Permanent anti-static polystyrene sheet | The surface resistance is as high as 10^6~10^9. |

| High-gloss polystyrene sheet | The surface high-gloss sheet is as bright as a mirror, and the surface has high gloss after blistering. |

| Matte surface polystyrene sheet | The product has an excellent matte effect after blister molding. |

| High impact polystyrene sheet (HIPS) | It is stronger than ordinary plastic sheet, has a softer feel, is not easy to break, and is resistant to low temperatures. |

| High barrier polystyrene sheet | It is widely used in food packaging at room temperature, which can effectively extend the shelf life. |

| Transparent polystyrene sheet | Transparent high-impact polystyrene sheet is widely used in food packaging and electronic tray packaging. |

| Anti-ultraviolet polystyrene sheet | Anti-ultraviolet sheet can be widely used outdoors, can prolong the service life of the product, and effectively prevent aging and discoloration. |

| laminated polystyrene sheet | The laminated sheet is composed of polyethylene film and high-impact polystyrene sheet, and the polyethylene film is made of high-temperature resistant film. Can effectively prevent scratches on the surface of the product. Various printing patterns can also be selected on the surface of the polyethylene film, which will not fall off after molding. |

Manufacturer Introduction of Thermoformed HIPS Plastic Rolls

The choose of Pulixin’s Thermoformed HIPS plastic rolls may be based on its high-quality brand reputation, rich experience and professional knowledge, diversified product lines, technological innovation and R&D capabilities, and environmental awareness.

1. Quality Brand and Reputation: Pulixin(Hongkong) is a well-known plastic products manufacturing company with a good brand reputation and long history. Choosing Desu’s products guarantees high quality and reliability.

2. Rich experience and expertise: Pulixin(Hongkong) Company has rich experience and expertise in the field of plastic products, and can provide comprehensive technical support and solutions to ensure that products can meet customer needs and standards.

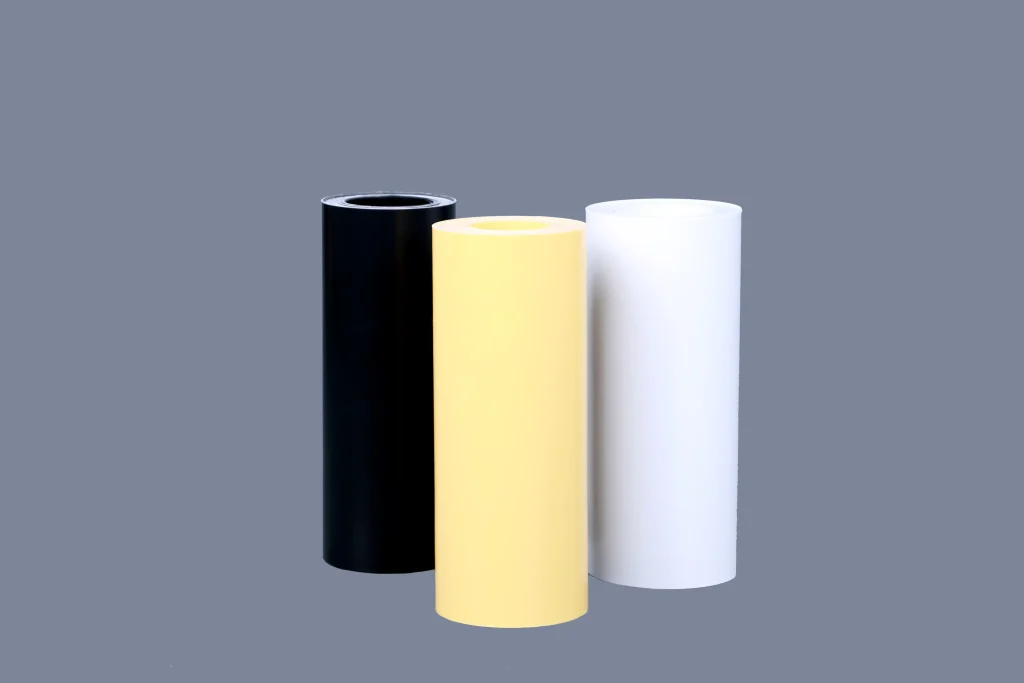

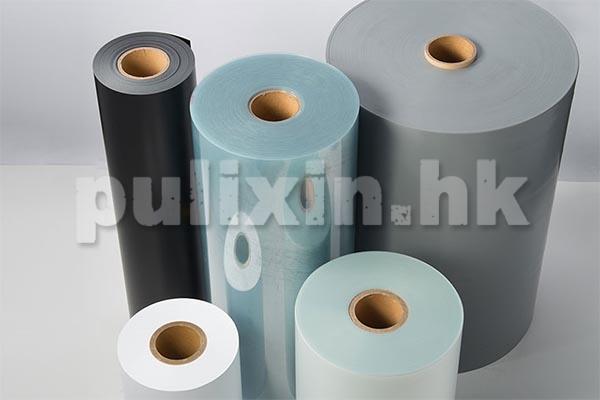

3. Diversified product lines: Pulixin(Hongkong) provides a variety of plastic coil products, including different specifications, colors, transparency, etc., which can meet the needs of various application scenarios.

4. Technological innovation and R&D capabilities: Pulixin(Hongkong) Company continues to carry out technological innovation and product research and development, and continuously introduces new materials and solutions to meet the changing market and customer needs.

5. Sustainable development and environmental awareness: Pulixin(Hongkong) Company pays attention to sustainable development and environmental awareness, and is committed to developing environmentally friendly materials and production processes to reduce the impact on the environment and meet the requirements of modern society for environmental protection and sustainable development.

| HIPS sheet type | Width (mm) | Thickness (mm) | Color | Resistance value (Ω) |

| HIPS normal sheet | 300-850 | 0.2-2.0 | Any/Customized | / |

| High impact HIPS | Any/Customized | / | ||

| HIPS black conductive | Black | 104-106 | ||

| HIPS black semi-conductive | Black | 106-109 | ||

| HIPS black volume conductive | Black | 104-106 | ||

| HIPS polymer sheet | Any/Customized | 108 | ||

| HIPS anti-static sheet | Any/Customized | 109-1011 | ||

| HIPS coated sheet | Any/Customized | 103-109 |