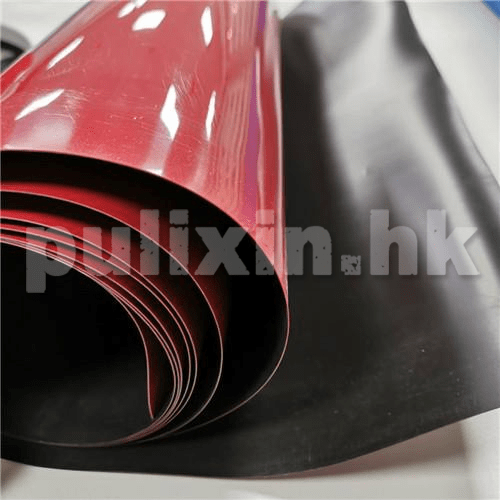

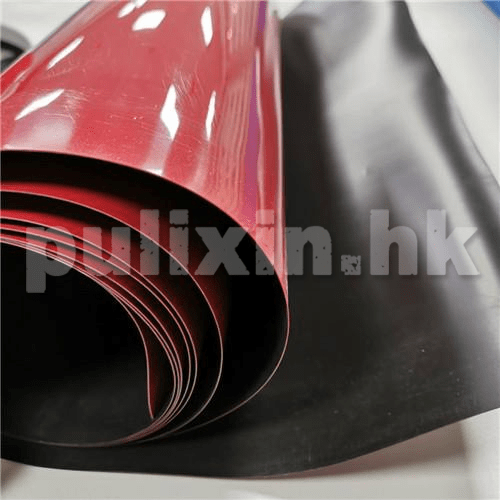

Double Color HIPS Sheet Rolls

Product Introduction of Double Color HIPS Sheet Rolls

Double Color HIPS (High Impact Polystyrene) Sheet Rolls are a type of plastic sheet that features two distinct colors, typically on either side of the sheet. The two colors are often achieved through co-extrusion, where two different colored resins are layered together during the production process. This results in a product that not only provides the durability and impact resistance of HIPS but also offers an attractive and customizable appearance.

Key Features of Double Color HIPS Sheet Rolls

1. Dual Color Layers: Offers an attractive two-tone appearance with different colors on each side, perfect for applications requiring visual appeal.

2. High Impact Resistance: Like standard HIPS Sheet Rolls, these sheets are durable and can withstand physical stress without cracking or breaking.

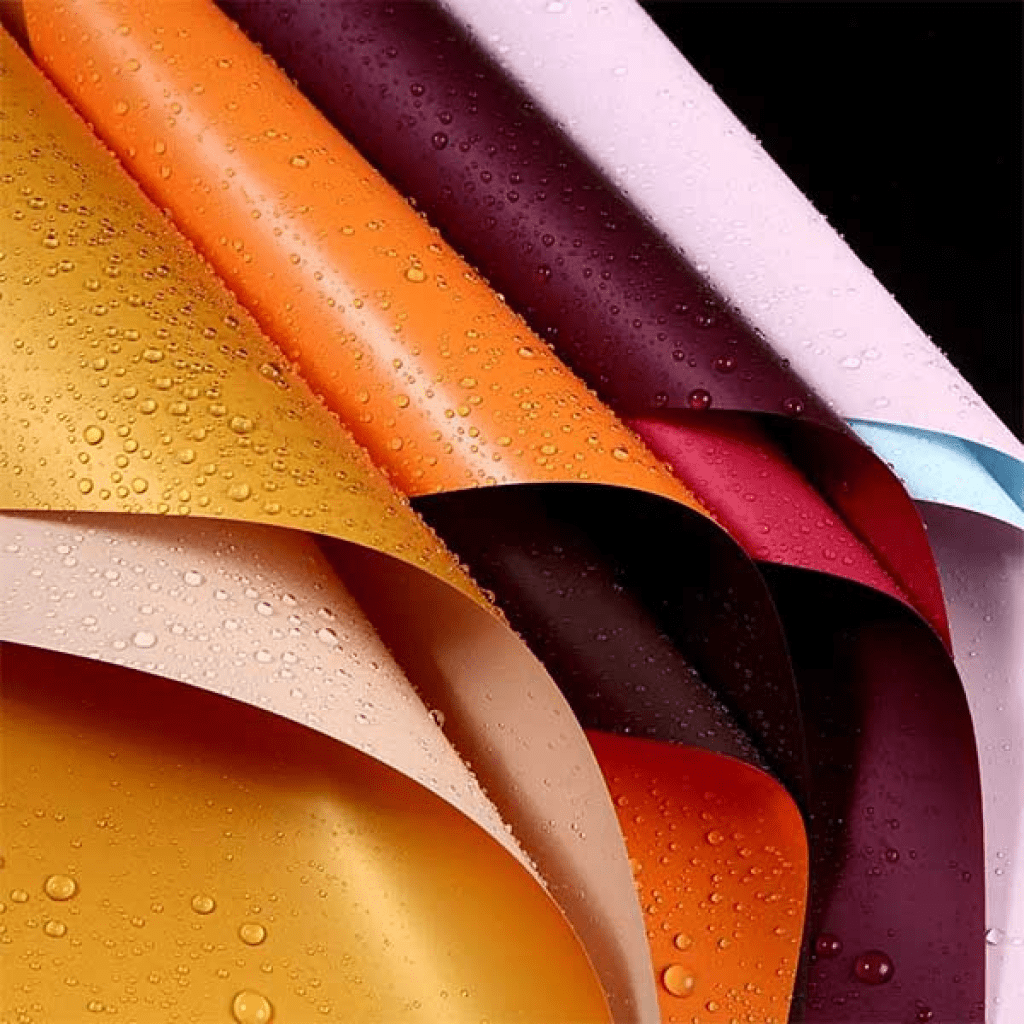

3. Customizable: Available in a wide range of color combinations to suit branding or design needs.

4. Thermoformable: Can be easily formed into complex shapes, ideal for packaging and promotional displays.

5. Cost-Effective: Provides the aesthetic value of a dual-color design at an affordable price compared to other more expensive materials.

Advantages

1. Vibrant Colors: Available in a wide spectrum of colors to meet design and branding needs.

2. Impact Resistant: High durability and strength, ideal for heavy-duty applications.

3. Flexible and Easy to Form: Ideal for thermoforming into custom shapes.

Product Application of Double Color HIPS Sheet Rolls

Double Color HIPS (High Impact Polystyrene) Sheet Rolls are widely used in packaging due to their striking color contrast, excellent formability, and cost-effectiveness, making them ideal for products that require visual appeal or brand differentiation. Below are specific packaging applications:

- Упаковка для пищевых продуктов

Bakery Products:

Dual-color cake boxes, pastry display trays (e.g., macaron boxes, cupcake containers), using layered colors to enhance a premium look.

Inner liners or outer boxes for mooncake and chocolate gift sets, paired with embossing or foil stamping.

Fast Food & Snacks:

Potato chip canisters, ice cream cup lids (colorful outer layer + white inner layer for hygiene and branding).

Flip-top packaging for candies and chewing gum (e.g., dual-color hinge boxes).

Advantages: HIPS complies with food-contact safety standards (e.g., FDA) and can be vacuum-formed into complex shapes.

- Electronics Packaging

Small Electronic Accessories:

Earphone cases, power bank shells, USB packaging inserts with dual-color designs to differentiate functional zones (e.g., transparent windows + colored borders).

Blister trays for smartphone stands or protective cases.

Premium Gift Packaging:

Gift box inserts for smartwatches or wireless earbuds, using contrasting colors to highlight products.

Advantages: Impact resistance + enhanced brand visibility.

- Cosmetics & Personal Care Packaging

Makeup Containers:

Lipstick tubes, compact cases, eyeshadow palettes (e.g., matte black outer layer + bright inner layer).

Decorative caps or pump heads for skincare products.

Perfume Display Boxes:

Foldable packaging with transparent windows and colored borders to boost shelf appeal.

Advantages: Suitable for screen printing or foil stamping, ideal for luxury positioning.

- Gift & Promotional Packaging

Festive Gift Boxes:

Limited-edition holiday packaging (e.g., red/gold for Lunar New Year or Christmas).

Blind box or capsule toy shells, where dual colors add unboxing excitement.

Promotional Displays:

Hanging blister packs for supermarket shelves (e.g., toothbrush + toothpaste combo packs).

Advantages: Eliminates extra printing costs by leveraging inherent material colors.

- Industrial & Tool Packaging

Tool Kits:

Blister trays for hardware tools or DIY parts (e.g., black base + yellow indicator layer).

Medical Device Packaging:

Sterilization blister packs for disposable instruments (must meet medical-grade standards).

Advantages: Wear-resistant and suitable for repeated opening/closing.

Product Parameter of Double Color HIPS Sheet Rolls

| Item | Double Color HIPS Sheet Rolls, High Impact Polystyrene Sheet Roll, HIPS Plastic Sheet, Rgid HIPS Film |

| Brand | Pulixin(Hongkong) Packaging Material |

| Origin | Shanghai, China |

| Ширина | 300~850mm |

| Толщина | 0.2~2.0mm |

| Weight | 50-150kg/roll |

| Shape | Roll/Sheet |

| Материал | 100% virgin |

| Цвет | Black, White, Color, Natural, Transparent, Translucent. |

| Performance | Conductive, Antistatic, EOVH High barrier |

| Surface treatment | Matte, high gloss, flocking, etc. |

How to process and produce Double Color HIPS Sheet Rolls?

The production of Double Color HIPS Plastic Rolls requires a specific manufacturing process, typically consisting of the following steps:

- Raw Material Selection

Select appropriate High Impact Polystyrene (HIPS) pellets, divided into two different colors (e.g., transparent, black, red, etc.), ensuring both physical properties and color stability.

The material selection should consider the final product's intended use, such as whether good impact resistance, surface hardness, and thermal stability are required.

- Mixing and Formulation

Mix the two different color HIPS pellets in a specific ratio while maintaining the layered color effect. The thickness of each color layer can be adjusted according to the requirements.

Use specific colorants or masterbatches to ensure accurate and even color distribution.

- Co-Extrusion Process

Use a co-extruder to simultaneously process the two color HIPS materials. The co-extrusion process allows the two different color HIPS plastics to be extruded through separate channels and then combined via a mold to form a dual-layer structure.

The two colors of HIPS materials are extruded from different outlets and merged in the co-extrusion mold, ultimately forming a double-colored HIPS sheet or film.

- Stretching and Molding

Thermoforming: Heat the plastic sheet to its softening temperature, then use thermoforming equipment (such as molds) to stretch it into the desired shape.

Cooling and Shaping: After stretching, use a cooling system to quickly cool the plastic sheet, setting it and maintaining the desired thickness and shape.

- Surface Treatment

Surface Polishing: Perform surface polishing or apply a glossy coating to ensure the product's aesthetic quality, improving its smoothness and gloss.

UV Coating: If necessary, add a UV-resistant coating to enhance the product's weather resistance and prevent color fading when exposed to sunlight for extended periods.

- Cutting and Packaging

Cut the produced double-color HIPS plastic rolls to the required specifications, ensuring that the width and length of the rolls meet the client's needs.

Finally, carry out packaging to ensure the product is protected during transportation.

- Quality Inspection

Perform a series of quality checks on the produced double-color HIPS plastic rolls to ensure the thickness, color consistency, strength, and impact resistance meet industry standards.

Inspect for issues such as bubbles, cracks, or uneven color distribution.

What is the difference between double color HIPS sheet rolls and single color HIPS Plastic Rolls?

| Aspect | Double color HIPS Plastic Rolls) | Single color HIPS Plastic Rolls) |

|---|---|---|

| Цвет | Double color HIPS plastic rolls feature two different colors, usually achieved by laminating two colors of plastic during the production process. This design is used for applications that need to highlight visual effects or differentiate different areas. | Single color HIPS plastic rolls are made from a single color, with uniform color throughout. The material is made from one type of plastic, resulting in a consistent color. |

| Appearance & Design | Double color HIPS rolls offer more design flexibility for packaging, display, or advertising, and are suitable for applications where visual impact is important. | Single color HIPS rolls are simpler in appearance, suitable for applications where excessive visual design is not needed. |

| Uses | Often used in high-end or attention-grabbing packaging, advertising, and artistic applications where better visual effects are needed. | Typically used in standard packaging applications, such as for food, electronics, and cosmetics, where a simple and consistent design is required. |