O principal fluxo de transformação dos rolos de chapa PET

The processing flow of PET (Polyethylene Terephthalate) sheet rolls involves several steps, from raw material preparation to the production of finished rolls ready for packaging and distribution. Here's the main processing flow of PET sheet rolls:

Raw Material Preparation:

PET resin pellets are obtained through polymerization processes, typically from petroleum-based feedstocks.

The PET resin pellets may undergo additional treatments or modifications to enhance specific properties such as clarity, strength, or barrier properties.

Extrusão:

The PET resin pellets are fed into an extruder, where they are melted and homogenized under high temperature and pressure.

The molten PET is then extruded through a flat die to form a continuous sheet of PET material.

Calendering or Casting:

The extruded PET sheet may undergo additional processing steps such as calendering or casting to achieve the desired thickness, smoothness, and surface finish.

Calendering involves passing the extruded sheet between a series of heated rollers to compress and flatten it.

Casting involves pouring the molten PET onto a cooled drum to solidify and form a sheet.

Cooling and Solidification:

After calendering or casting, the PET sheet is cooled rapidly to solidify it into a stable form.

Cooling methods may include air cooling or water quenching, depending on the desired characteristics of the final sheet.

Trimming and Slitting:

Once solidified, the PET sheet is trimmed to remove any irregular edges or surface defects.

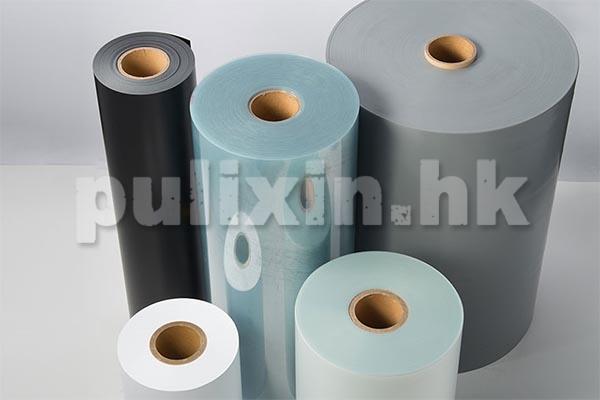

The sheet may then be slit into narrower rolls of varying widths, depending on customer requirements and end-use applications.

Quality Control:

Throughout the processing flow, quality control measures are implemented to ensure that the PET sheet meets specified standards for thickness, clarity, strength, and other properties.

This may involve inline monitoring, sampling, and testing of the sheet at various stages of production.

Packaging and Storage:

The finished PET sheet rolls are packaged and labeled for shipment to customers or storage in warehouses.

Proper packaging and storage conditions are maintained to prevent damage, contamination, or degradation of the sheet rolls.

Throughout the processing flow, strict adherence to quality standards, process control, and safety protocols is essential to ensure the production of high-quality PET sheet rolls that meet the requirements of various industries, including packaging, printing, electronics, and automotive. Continuous improvement efforts and advancements in technology further enhance the efficiency, productivity, and sustainability of PET sheet roll production processes.