0.8 mm PET Plastic Sheet Rolls

Guia de parâmetros

| Categoria: | Rolo de chapa plástica PETG termoformável |

| Processo: | Co-Extrusão Squeeze Out |

| Espessura: | 0,18mm-2mm |

| Largura: | 300mm-850mm |

| Cor: | Claro / Transparente / Preto / Branco / Cor personalizada |

| Forma e peso: | Até 150 kg/rolo |

| Certificado: | SGS, ISO9001,ISO14001 |

| Temperatura: | -30℃-120℃ |

Descrição do produto

Product Introduction of 0.8 mm PET Plastic Sheet Rolls

0.8 mm PET plastic sheet roll is a thin sheet made of PET (polyethylene terephthalate) plastic material with a thickness of 1.8 mm. PET is a plastic known for its clarity, strength and versatility. Due to its properties, including its transparency and durability, 1.8mm PET plastic sheet roll is often used in packaging areas where flexibility and transparency are very important.

Product Advantage of 0.8 mm PET Plastic Sheet Rolls

1. Transparency: 0.8 mm PET plastic sheet roll has a high degree of transparency, making it ideal for applications requiring clear or translucent materials. This makes it ideal for creating clear coverings, display windows, clear packaging and other products that require good visibility.

2. Lightwight: 0.8 mm PET plastic sheet roll are very light, making them useful in applications where lightweight materials are required. For example, it can be used in lightweight packaging materials to reduce the burden of transportation and carrying.

3. Durability: 0.8 mm PET plastic sheet roll has excellent wear and tear resistance, making it ideal for applications that require material durability and strength. It won’t tear or break easily, making it suitable for use where other items need to be protected or covered.

4. High temperature stability: 0.8 mm PET plastic sheet roll has good high temperature stability and can work under higher temperature conditions without losing its performance. This makes it very useful in some heat-sensitive applications.

5. Chemical Stability: 0.8 mm PET plastic sheet roll has good resistance to many common chemicals and solvents, which means it can be used in a variety of chemical environments without severe corrosion or decomposition.

6. Recyclability: 0.8 mm PET plastic sheet roll is a recyclable plastic that helps reduce environmental impact and promotes sustainable materials management.

Product Application of 0.8 mm PET Plastic Sheet Rolls

1. Packaging: 0.8 mm PET plastic sheet rolls are often used for packaging materials such as blister packs, clamshells, and trays due to their transparency and ability to protect products.

2. Graphics: Thin 0.8 mm PET plastic sheet rolls are used in graphic applications, such as printing and signage, where a clear and rigid substrate is needed.

3. Electronics: 0.8 mm PET plastic sheet rolls is used in the manufacturing of electronic components, including flexible printed circuits and displays.

4. DIY Projects: It can be used in DIY projects, crafts, and model making due to its versatility and ease of cutting.

5. Manufacturing Processes: 0.8 mm PET plastic sheet rolls can be produced through processes like extrusion or calendering, where the plastic is melted and then formed into a thin sheet.

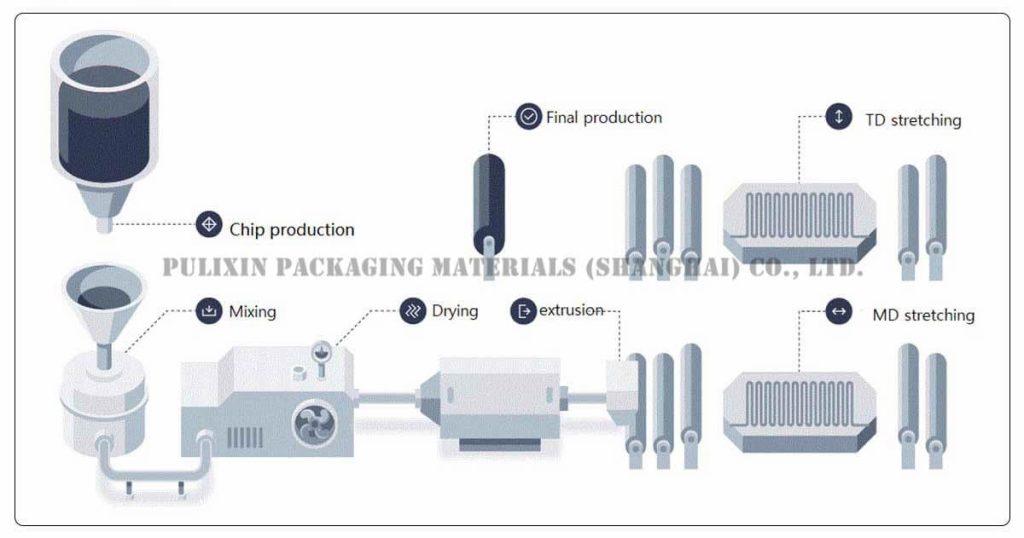

Product Production of 0.8 mm PET Plastic Sheet Rolls

The production of PET plastic sheet rolls with a thickness of 0.8 mm is a complex process involving the control of multiple parameters such as equipment, temperature, pressure and speed. The production process needs to be strictly controlled to ensure the stability and quality of the product.

1. Raw material preparation: PET resin that meets the quality standards is selected as the raw material for producing 0.8mm PET plastic sheet rolls.

2. Melt extrusion: Put the PET resin into the hopper of the extruder. The extruder heats and melts the resin through a pair of screws, and pushes the molten plastic to the extrusion head (die) of the extruder.

3. Extrusion head design: The design of the extrusion head should meet the required film or sheet thickness requirements (0.8 mm). The die shape and size of the extrusion head will directly affect the extruded film thickness.

4. Extrusion and cooling: Under the action of the extrusion head, the molten PET plastic is extruded through the die to form a film or sheet of plastic. During extrusion, proper cooling needs to be ensured to maintain the shape and thickness of the plastic.

5. Calendering: Extruded film or sheet plastic is processed through calender rolls to ensure a consistent thickness and flat surface.

6. Cooling and solidification: The calendered plastic film or sheet material is cooled by a cooling device to solidify and stabilize its size.

7. Coiling: The cooled and solidified PET plastic film or sheet material passes through the coiling device and is rolled into a roll to form a 0.8 mm PET plastic sheet roll.

8. Inspection and packaging: Quality inspection is carried out on the produced PET plastic sheet rolls to ensure that their thickness and other specifications meet the requirements. The plastic sheet rolls are then packaged and stored for dispatch or further processing.

Product Parameter of 0.8 mm PET Plastic Sheet Rolls

| Nome do produto | 0.8 mm PET Plastic Sheet Rolls |

| Material | 100% matéria-prima PET virgem |

| Cor | Qualquer cor |

| Certificado | SGS, ROHS, ISO, etc. |

| Grau | Qualidade médica, qualidade alimentar e qualidade condutora |

| Largura | 300~1400mm |

| Espessura | 0.8 mm |

| Aplicação | Aplicado principalmente na embalagem de alimentos, medicamentos, electrónica, cosméticos e presentes. |

| A nossa vantagem | 1. equipa QC rigorosa, taxa de satisfação de qualidade cumpre 99% 2.Mais de 10 conjuntos de equipamentos automatizados avançados, cumprem os requisitos de qualidade de ponta 3. serviço de design gratuito e tempo de execução rápido da amostra em 3 dias |

| Tempo de amostragem | 1-3 dias |

| Métodos de entrega | Transporte marítimo, transporte aéreo, transporte expresso, transporte terrestre |

| Prazo de pagamento | Cartão de crédito, T/T, L/C, Western Union, Paypal |

| Transparência | Transparência,Semi-transparência,Opaco |

| Superfície | Brilhante/mate |

1

POR QUE NOS ESCOLHERMais >>

Clique para ver a oficina, equipamento, qualificação certificada e força da vantagem de Pulixin(HK)- Um fabricante profissional de chapa PP PS PET

Não Comerciante mas Fábricas

Até 100% Material Virgem

Experiência, certificação e patente

Inspecção de qualidade de alto nível

Várias linhas avançadas 7-12 dias de entrega

Embalagem segura para transporte internacional

Aplicação do produto

0.8 mm PET Plastic Sheet Rolls normalmente tem uma ampla gama de uso, como embalagens de produtos de consumo, bandeja eletrônica, alimentos frescos Crisper, embalagens cosméticas, embalagens de blister de dispositivos médicos.