PET ESD plastic sheet roll

Parameters Guide

| Category: | Conductive ESD Antistatic PS PP PET Sheet |

| Process: | Co-Extrusion Squeeze Out |

| Thickness: | 0.18mm-2mm |

| Width: | 300mm-850mm |

| Color: | Clear / Transparent / Black / White / Customize Color |

| Shape&Weight: | Up to 150kg/Roll |

| Certificate: | SGS, ISO9001,ISO14001 |

| Temperature: | -30℃-120℃ |

Product Description

Introduction Of PET ESD plastic sheet roll

PET ESD plastic sheet rolls are specialized materials used in industries where electrostatic discharge (ESD) protection is crucial.

Material: PET (Polyethylene Terephthalate) is the base material, known for its transparency, durability, and chemical resistance.

ESD Properties: These sheets are engineered to dissipate static electricity, preventing damage to sensitive electronic components during handling or storage.

Applications: Commonly used in manufacturing environments for electronics, telecommunications equipment, medical devices, and other industries where ESD can cause malfunctions or failures.

Roll Format: Supplied in roll form for efficient handling and storage, typically in widths and lengths that suit industrial processing equipment.

Customization: Can be customized with treatments or coatings to enhance ESD performance or other specific requirements.

Characteristics of PET ESD plastic sheet rolls

Surface Resistance: Low surface resistance to ensure effective static dissipation.

Thickness: Available in various thicknesses depending on application requirements.

Transparency: Often transparent or translucent, allowing visual inspection without removing the protective layer.

Environmental Considerations: PET is recyclable, which aligns with sustainability goals in manufacturing.

Application Of PET ESD plastic sheet roll

PET ESD (Electrostatic Discharge) plastic sheet rolls are typically used for packaging products that require electrostatic protection. These products often include electronic components, semiconductors, integrated circuits, precision instruments, and more. The importance of electrostatic protection lies in preventing damage or performance issues caused by electrostatic discharge (ESD).

Specifically, PET ESD plastic sheet rolls are suitable for packaging:

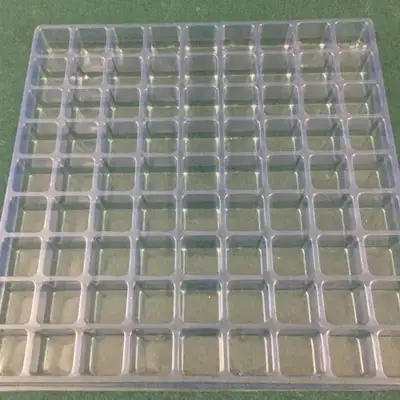

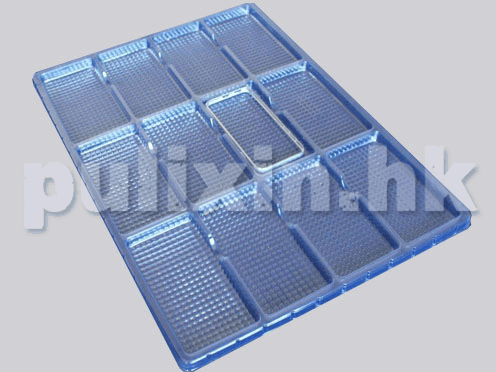

1. Electronic components and semiconductor devices: Such as chips, circuit boards, resistors, capacitors, etc. These components are highly sensitive to electrostatic discharge, necessitating the use of electrostatic protective materials for packaging and transportation to prevent ESD damage.

2. Precision instruments and equipment: Including various measuring instruments, optical devices, medical equipment, and other sensitive instruments. These devices may experience performance impacts from electrostatic influences, hence requiring electrostatic protection during packaging and transportation.

3. Packaging needs for anti-static products: Besides the mentioned product types, any product that requires protection against static buildup or electrostatic discharge that could potentially affect its functionality can benefit from PET ESD plastic sheet rolls.

Specification Of PET ESD plastic sheet roll

| PET ESD plastic sheet roll PROPERTY | UNIT | SA Coated | Print Level | Antiblock Silicon Free | Antistatic Silicon Free |

| THICKNESS OF FILM TESTED | mm | 0.13~ 1.8 | 0.3~0.6 | 0.13~1.8 | 0.25~1.8 |

| WIDTH | mm | 350~ 1400 | 350~ 1300 | 600~ 1400 | 600~ 1400 |

| DIAMETER | 300~ 800 | 300~ 800 | 300~ 800 | 300~ 800 | |

| DENSITY | g/cm3 | 1.35 | 1.35 | 1.35 | 1.35 |

| HAZE | % | 0.7(0.3mm) | 0.7(0.3mm) | 0.8(0.3mm) | 2.0(0.3mm) |

| TOTAL LIGHT TRANSMITTANCE | % | 92(0.3mm) | 91(0.3mm) | 91(0.3mm) | 89(0.3mm) |

| MATERIAL | Conductive | Static dissipation | Anti-static | Coated PET | Coated PET |

| SURFACE RESISTANCE | (Ω/SQ) | 103 to 105 | 105 to 109 | 109 to 1012 | 106 10 4 |

Advantages Of PET ESD plastic sheet roll

PET ESD (Electrostatic Discharge) plastic sheet rolls offer several advantages, particularly in applications where static electricity control is crucial. Here are some key advantages:

1. Static Electricity Control: The primary advantage of PET ESD plastic sheet rolls is their ability to dissipate static electricity. This property is essential in environments where electrostatic discharge can damage sensitive electronics or create hazards in explosive atmospheres.

2. Protection of Electronics: These sheets are commonly used as protective packaging for electronic components and devices. By preventing static buildup, they safeguard sensitive electronics from potential damage during handling, shipping, and storage.

3. Durability: PET (Polyethylene Terephthalate) is known for its toughness and durability. ESD PET sheets maintain these characteristics, providing robust protection while also being lightweight and flexible.

4. Transparency: PET ESD sheets are transparent, allowing for easy visual inspection of packaged items without the need for unpacking. This transparency is advantageous in quality control and inventory management processes.

5. Chemical Resistance: They offer good resistance to many chemicals, which enhances their suitability for various industrial and electronic applications where exposure to solvents or cleaning agents might occur.

6. Versatility: PET ESD plastic sheet rolls are versatile and can be easily fabricated into different forms such as bags, sleeves, covers, and trays. This flexibility makes them adaptable to a wide range of packaging and static-control requirements.

7. Environmental Benefits: PET is recyclable, making PET ESD sheets a more environmentally friendly option compared to some other materials used for similar purposes.

WHY CHOOSE USMore >>

Click to see workshop, equipment, certificated qualification and advantage strength of Pulixin(HK)- A professional PP PS PET sheet manufacturer

Not Trader But Factories

Up to 100% Virgin Material

Experience, Certification & Patent

High-standard Quality Inspection

Multiple Advanced Lines 7-12 Days Delivery

Safe Packing For International Transport

Product Application

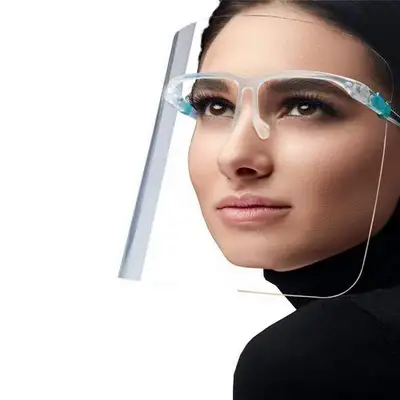

PET ESD plastic sheet roll normally has a wide range of useage like consumer product packaging, electronic tray, fresh food Crisper,cosmetic packaging, Medical device blister packaging.