PET blister sheet rolls

Guide des paramètres

| Catégorie : | Rouleau de feuille de plastique APET pour le thermoformage |

| Processus : | Co-Extrusion Squeeze Out |

| Épaisseur : | 0,18mm-2mm |

| Largeur : | 300mm-850mm |

| Couleur : | Clair / Transparent / Noir / Blanc / Couleur personnalisée |

| Forme et poids : | Jusqu'à 150 kg/rouleau |

| Certificat : | SGS, ISO9001, ISO14001 |

| Température : | -30℃-120℃ |

Description du produit

Product Introduction of PET blister sheet rolls

PET blister sheet rolls, known for its exceptional performance and environmental advantages, is gaining popularity in the Middle Eastern market as a transparent packaging material that is quietly revolutionizing the food packaging industry. It acts like an invisible protective film, securely locking in the freshness of fruits and vegetables, providing comprehensive protection for your products.

PET, short for polyethylene terephthalate, is a type of polymer material. The inception of PET blister sheet rolls can be traced back to the inventions of scientists in the 1930s, and it has stood out through continuous improvements and innovations. With its exceptional performance and environmental benefits, PET has gradually become a favorite in the packaging industry.

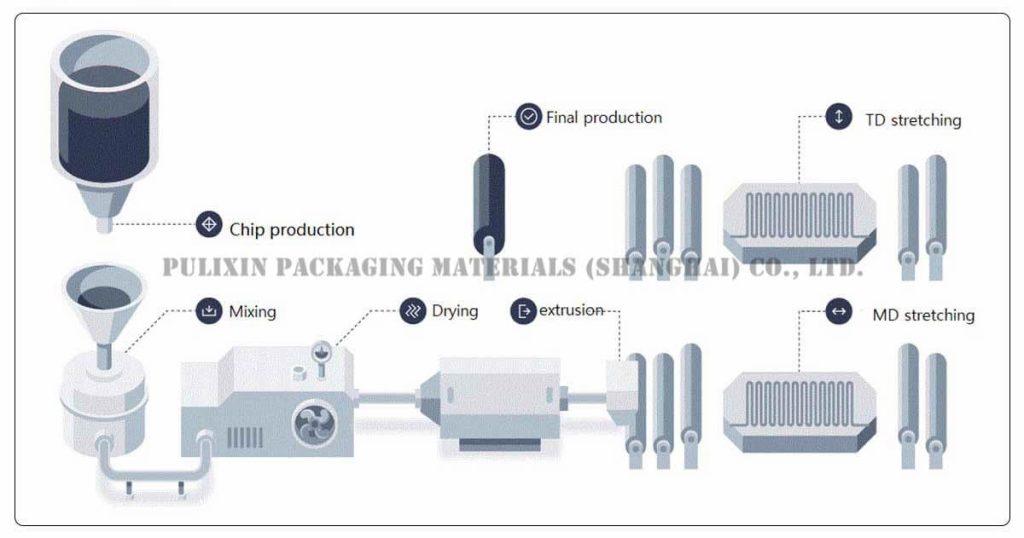

Production Process of PET blister sheet rolls

Here's the version of the PET blister sheet roll production process:

Raw Material Preparation

1. PET Slices: High-quality PET slices are purchased from suppliers.

2. Additives: Stabilizers, antioxidants, colorants, etc., are added as needed.

Drying Process

PET slices are dried in a drying machine to remove moisture, preventing the formation of bubbles or other defects during production.

Extrusion Molding

1. Feeding: Dry PET slices are fed into the feeding port of an extruder.

2. Melt Extrusion: PET slices melt into a viscous fluid inside the extruder through heating and the action of screws.

3. Filtration: The molten PET passes through a filter to remove impurities.

Mold Forming

1. Extrusion through Die: Molten PET is extruded into thin sheets through a die.

2. Cooling and Shaping: The extruded sheets are cooled and shaped using cooling rollers or a water cooling system.

Stretching and Traction

1. Longitudinal Stretching: The sheets are stretched longitudinally on a stretching machine to improve their mechanical properties and transparency.

2. Traction: The sheets are pulled out evenly through a traction device to ensure uniform thickness.

Rolling

The formed sheets are rolled into rolls for storage and transportation.

Inspection and Packaging

1. Quality Inspection: Quality checks are conducted on the produced rolls to inspect thickness, transparency, mechanical properties, etc.

2. Packaging: Qualified rolls are packaged, and production batch and specifications are labeled.

Production Advantages of PET blister sheet rolls

PET blister sheet rolls offer several production advantages, making them a preferred choice in various industries. Here are some of the key advantages:

1. Versatility: PET blister sheet rolls can be customized to meet specific requirements in terms of thickness, size, and shape, making them suitable for a wide range of packaging applications.

2. Excellent Transparency: PET has excellent optical properties, providing high clarity and transparency, which is crucial for showcasing products effectively.

3. Impact Resistance: PET blister sheet rolls offer good impact resistance, protecting packaged items from damage during handling and transportation.

4. Chemical Resistance: PET is resistant to many chemicals, oils, and greases, making it suitable for packaging a variety of products, including pharmaceuticals, cosmetics, and food items.

5. Ease of Processing: PET can be easily processed using various techniques such as extrusion, thermoforming, and heat sealing, allowing for efficient production processes.

6. Lightweight: PET blister sheet rolls are lightweight, reducing packaging weight and transportation costs while maintaining strength and durability.

7. Environmental Sustainability: PET is recyclable, and the recycled material can be used to produce new blister sheet rolls or other PET products, contributing to environmental sustainability.

8. Cost-Effectiveness: PET blister sheet rolls offer a cost-effective packaging solution compared to alternatives like PVC or polystyrene, providing excellent performance at a competitive price point.

9. FDA Compliance: PET is approved by regulatory authorities such as the FDA for direct contact with food, pharmaceuticals, and other sensitive products, ensuring safety and compliance with industry regulations.

Future prospects for PET blister sheet rolls

The future prospects for PET blister sheet rolls look promising, driven by several factors:

1. Growing Demand for Sustainable Packaging: With increasing awareness of environmental issues, there's a rising demand for sustainable packaging solutions. PET is recyclable and offers a lower carbon footprint compared to other materials like PVC. As companies and consumers prioritize eco-friendly options, PET blister sheet rolls are likely to see continued growth in demand.

2. Expansion in End-Use Industries: PET blister sheet rolls find applications across various industries, including pharmaceuticals, food and beverage, cosmetics, and consumer goods. As these industries continue to grow globally, especially in emerging markets, the demand for PET blister sheet rolls is expected to rise correspondingly.

3. Advancements in PET Recycling: Technological advancements in PET recycling processes are making it easier and more cost-effective to recycle PET material. This enhances the sustainability credentials of PET blister sheet rolls and contributes to a circular economy approach, where PET can be recycled and reused in packaging applications.

4. Innovations in Packaging Design: As consumer preferences evolve, there's a growing demand for innovative packaging designs that offer convenience, functionality, and aesthetic appeal. PET blister sheet rolls can be customized in terms of size, shape, and transparency, allowing for creative packaging solutions that meet these evolving consumer demands.

5. Regulatory Support: Regulatory bodies are increasingly focusing on promoting sustainable packaging materials and practices. PET is already widely approved for use in food and pharmaceutical packaging by regulatory authorities such as the FDA and EFSA. Continued support from regulators for PET packaging materials will further boost their adoption in the market.

6. Technological Advancements: Ongoing advancements in manufacturing technologies, such as improved extrusion and thermoforming processes, are enhancing the efficiency and cost-effectiveness of producing PET blister sheet rolls. This enables manufacturers to meet growing demand while maintaining competitive pricing.

The future prospects for PET blister sheet rolls are bright, driven by the increasing demand for sustainable packaging solutions, expansion in end-use industries, advancements in recycling technologies, innovations in packaging design, regulatory support, and technological advancements in manufacturing processes.

POURQUOI NOUS CHOISIRPlus >>

Cliquez pour voir l'atelier, l'équipement, la qualification certifiée et les avantages de Pulixin(HK)- Un fabricant professionnel de feuilles PP PS PET.

Pas de commerçants, mais des usines

Jusqu'à 100% Matériau vierge

Expérience, certification et brevet

Inspection de qualité de haut niveau

Lignes avancées multiples 7-12 jours de livraison

Emballage sûr pour le transport international

Application du produit

PET blister sheet rolls Il est normalement utilisé pour l'emballage de produits de consommation, de plateaux électroniques, d'aliments frais, d'emballages cosmétiques et de blisters pour les appareils médicaux.