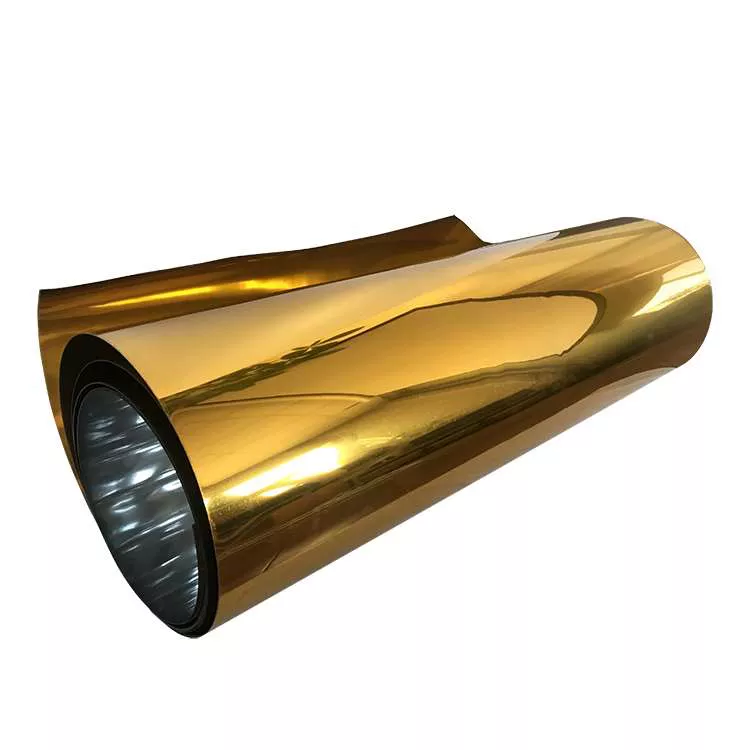

Rouleau de plastique HIPS extrudé pour barquette en plastique blister

Guide des paramètres

| Catégorie : | Rouleau de feuille de plastique PS pour thermoformage |

| Processus : | Co-Extrusion Squeeze Out |

| Épaisseur : | 0,18mm-2mm |

| Largeur : | 300mm-850mm |

| Couleur : | Clair / Transparent / Noir / Blanc / Couleur personnalisée |

| Forme et poids : | Jusqu'à 150 kg/rouleau |

| Certificat : | SGS, ISO9001, ISO14001 |

| Température : | -30℃-120℃ |

Description du produit

Extruded HIPS plastic roll,hips plastic blister roll, hips plastic roll density of the blister sheet is the density of polystyrene, the amorphous density is 1.04 to 1.06 g / cm3, and the crystal density is 1.11 to 1.12 g / cm3. The melting temperature is 240 ° C, and the resistivity is 1020 to 1022 ohm · cm.

Extruded HIPS plastic roll,hips plastic blister roll, hips plastic roll that is, polystyrene, refers to a polymer synthesized from a styrene monomer through a radical addition polymerization reaction. It is a colorless and transparent thermoplastic with a glass transition temperature above 100 ° C, so it is often used to make a variety of disposable containers that need to withstand the temperature of boiling water, and disposable foam lunch boxes.

Extruded HIPS plastic roll,hips plastic blister roll, hips plastic roll detail information:

A. The thickness of ordinary thin blister is 0.14 ~ 5.0mm — it is mainly made of various materials and effects such as PP, PS (HIPS), PET (including APET and PETG), and recyclable paper tray. Non-thermoformed plastic products such as hemming, folding, tri-folding, cylinder, folding box, heaven and earth box, high frequency, etc. are widely used in food, medicine, electronics, toys, computers, daily necessities, cosmetics and machinery hardware industries. B. Special thick blister thickness is 0.14 ~ 8.0mm ———— It is mainly used for injection molding of various materials and effects such as PP, PS (HIPS), PET (including APET and PETG)

The characteristics and advantages of Extruded HIPS plastic roll,hips plastic blister roll, hips plastic roll blister light box: 1. Colorful, eye-catching effect, good light transmission, uniform and soft light. 2. High temperature resistance, climate change resistance, and environmental protection 3. Not easy to deform and fade (generally can maintain color for 8-10 years) 4. Good corrosion resistance 5. Rainproof, fireproof and anti-combustible acrylic (Extruded HIPS plastic roll,hips plastic blister roll, hips plastic roll) is in recent years A new type of outdoor media introduced from abroad, as an avant-garde propaganda product in the advertising industry, has a strong three-dimensional sense, rich colors, and low cost. It has been favored by customers, and its application and development are fast.Extruded HIPS plastic roll,hips plastic blister roll, hips plastic roll mainly used in: 1. Architecture, such as: shop windows, soundproof door walls, lighting covers, solar collectors, telephone booths. 2. Advertising display categories, such as: light boxes, signboards, signs, display stands, ball covers, and guide signs. 3. Industrial products, such as: instrument panels, machine covers, flow meters, and automotive taillight housings. 4. Lighting, such as: fluorescent lampshades, various shapes of lampshades for environmental purification equipment. 5, civilian categories, such as: bathroom equipment, dressing tables, photo frames, shelves, gifts, souvenirs, backseats of cool chairs, candy boxes, information shelves, food covers, high-grade aquariums. 6. Medical, such as baby incubators, kits, thermostats, operation cabinets. 7. Special applications, such as windows and windshields for aircraft, yachts and automobiles, periscopes for submarines and trenches, etc.

| Test Item | Test method | Unit | Properties |

| Specific gravity | ASTM D792 | g/cm3 | 1.04 |

| Impact Strength | ASTM D256 | mpa | 35 |

| Tensile Strength | ASTM D638 | mpa | 29 |

| Heat Deflection Temperature | ASTM D648 | ℃ | 85 |

| Flexural Strength | ASTM D790 | mpa | 36 |

| COULEUR | Visual Inspection | / | White (Colorable) |

| SURFACE RESISTANCE | ASTM D257 | Ω | 1011 |

POURQUOI NOUS CHOISIRPlus >>

Cliquez pour voir l'atelier, l'équipement, la qualification certifiée et les avantages de Pulixin(HK)- Un fabricant professionnel de feuilles PP PS PET.

Pas de commerçants, mais des usines

Jusqu'à 100% Matériau vierge

Expérience, certification et brevet

Inspection de qualité de haut niveau

Lignes avancées multiples 7-12 jours de livraison

Emballage sûr pour le transport international

Application du produit

Rouleau de plastique HIPS extrudé pour barquette en plastique blister Il est normalement utilisé pour l'emballage de produits de consommation, de plateaux électroniques, d'aliments frais, d'emballages cosmétiques et de blisters pour les appareils médicaux.