Conductive PP Plastic Sheet

Parameters Guide

| Category: | Thermoforming PP Plastic Sheet Roll |

| Process: | Co-Extrusion Squeeze Out |

| Thickness: | 0.18mm-2mm |

| Width: | 300mm-850mm |

| Color: | Clear / Transparent / Black / White / Customize Color |

| Shape&Weight: | Up to 150kg/Roll |

| Certificate: | SGS, ISO9001,ISO14001 |

| Temperature: | -30℃-120℃ |

Product Description

Brief introduction of Conductive PP Plastic Sheet

Conductive PP plastic sheet refers to a plastic sheet that adds conductive additives to the polypropylene (PP) substrate to make it conductive. Conductive additives can be carbon black, carbon fiber, metal powder, conductive polymer, etc.

Conductive additives form conductive paths in the PP matrix, allowing electrons to flow through them. The number and structure of the conductive paths determine the conductive properties of the PP conductive plastic sheet.

There are two processing forms for the PP conductive plastic sheet produced by PULIXIN(hongkong). One is to add carbon black to the PP substrate (only black PP conductive plastic sheet is made), and the other is to apply polymer conductive liquid on the PP surface. If you need to purchase conductive PP plastic sheet, please contact us and we will formulate conductive PP blister sheet rolls according to your needs.

Characteristics of Conductive PP Plastic Sheet

Conductivity: The surface resistivity of Conductive PP plastic sheet is generally between 10^3-10^9 Ω·cm, which can meet general conductive applications.

Processing performance: Conductive PP plastic sheet has good processing performance and can be formed by injection molding, extrusion, blown film and other methods.

Mechanical properties: Conductive PP plastic sheet has good mechanical properties, including tensile strength, bending strength, impact strength, etc.

Chemical resistance: Conductive PP plastic sheet has good chemical resistance and can withstand corrosion from a variety of acid and alkali chemicals.

Cost-effectiveness: Conductive PP plastic sheet has a better cost-effectiveness than other conductive sheets, such as metal sheets, conductive rubber, etc.

Advantages of Conductive PP Plastic Sheet

Light weight: The density of Conductive PP plastic sheet is much lighter than that of metal sheet, so it has the advantage of light weight.

Easy to process: Conductive PP plastic sheet has good processing performance and can be formed by a variety of methods.

Low cost: Conductive PP plastic sheet has a better cost-effectiveness than other conductive sheets.

Recyclable: Conductive PP plastic sheet can be recycled and meets environmental protection requirements.

Specifications of Conductive PP Plastic Sheet

| roduct Name | Conductive PP Plastic Sheet |

| Material | 100% virgin PP raw material |

| Color | Natural, Color, Black, White, Transparent, Translucent, etc. |

| Certificate | SGS, ROHS, ISO, etc. |

| Grade | Medical grade, food grade and conductive grade |

| Width | 300~1400mm |

| Thickness | 0.2~2mm |

| Composite | PP+PE, PP+EVOH+PE, PP+EVOH+PP |

| Application | Mainly applied to the packaging of food, medicine, electronics, cosmetics, gifts, etc. |

| Sample Time | 1-3 days |

| Delivery Methods | Ocean shipping ,air transportation, express,land transportation |

| Payment Term | Credit card ,T/T, L/C, Western Union, Paypal |

| Transparency | Transparency, Semi-transparency, Opaque |

| Surface | Glossy/Matt |

| Form | By roll or cut sheet form |

Production process of Conductive PP Plastic Sheet

The production process of conductive dissipative PP sheets usually includes the following steps:

Mixing: Mixing PP resin with other additives such as pigments and antistatic agents.

Extrusion: The mixture is heated and extruded into a film or sheet.

Cooling: Cooling the film or sheet to room temperature.

Shaping: The film or sheet is heated and blistered into the desired shape.

Trimming: Trimming molded parts as needed, such as cutting, stamping, or printing.

How to make Conductive PP plastic sheets

Adding conductive fillers: The most common method is to add conductive fillers, such as carbon black, carbon fiber or metal powder, to PP resin. These fillers increase the material's conductivity, allowing it to conduct electricity.

Use a conductive coating: Another method is to apply a conductive coating on the surface of the PP sheet. Coatings can be made from conductive inks, paints or metallic films.

Use chemical modification: PP resin can also be chemically modified to make it conductive. This usually involves adding additives to the resin, such as peroxides or coupling agents, which change the chemical structure of the material so that it can conduct electricity.

Pros and cons of each method:

| Method | Advantages | Disadvantages |

| Adding conductive fillers | Low cost and easy to process | May reduce the mechanical properties of the material |

| Use conductive coating | Can maintain the original characteristics of the material | Coating may wear or peel |

| Use chemical modification | High electrical conductivity can be achieved | Complex process and high cost |

Application of Conductive PP plastic sheets

Conductive dissipative PP sheets have a wide range of applications, including:

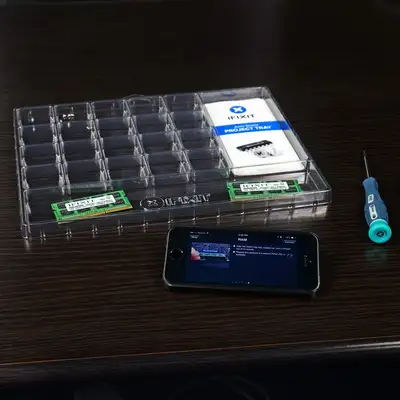

Electronic product packaging and shipping: Conductive dissipative PP sheets can be used to make electronic component trays, packaging boxes and other materials used to ship electronic products. It can help prevent ESD from damaging sensitive electronic components.

Industrial Applications: Conductive PP plastic sheet can be used as conveyor belts, guide rails, and other industrial components where static buildup needs to be prevented.

Medical device packaging: Conductive PP plastic sheet can be used in the packaging of medical devices to prevent ESD damage.

Food packaging: Conductive PP plastic sheet can be used in food packaging to prevent fires or explosions caused by static electricity accumulation.

Other Applications: PP conductive plastic sheets can also be used in other applications such as anti-static flooring, walls and clothing.

WHY CHOOSE USMore >>

Click to see workshop, equipment, certificated qualification and advantage strength of Pulixin(HK)- A professional PP PS PET sheet manufacturer

Not Trader But Factories

Up to 100% Virgin Material

Experience, Certification & Patent

High-standard Quality Inspection

Multiple Advanced Lines 7-12 Days Delivery

Safe Packing For International Transport

Product Application

Conductive PP Plastic Sheet normally has a wide range of useage like consumer product packaging, electronic tray, fresh food Crisper,cosmetic packaging, Medical device blister packaging.