Conductive APET Plastic Sheet for Electronic Products

Parameters Guide

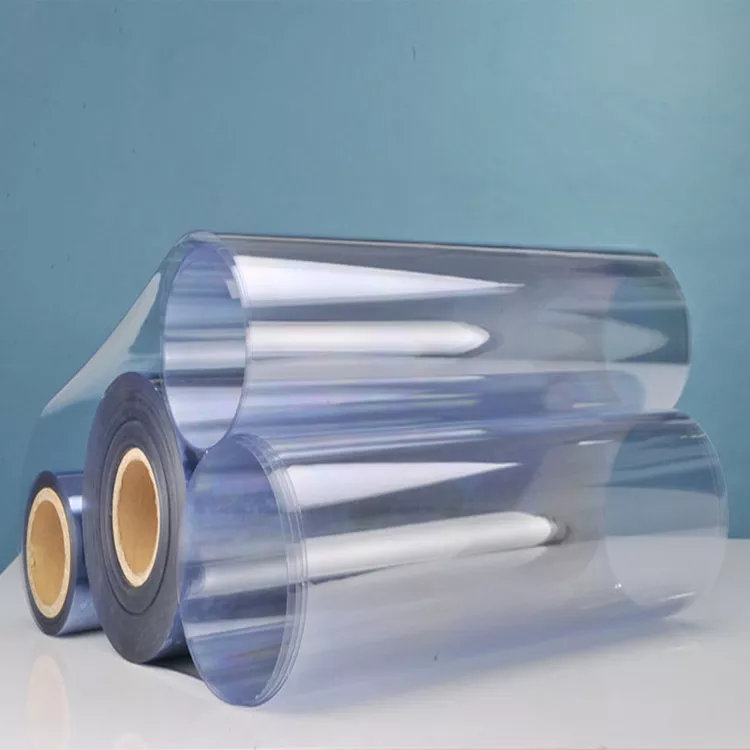

| Category: | Thermoforming APET Plastic Sheet Roll |

| Process: | Co-Extrusion Squeeze Out |

| Thickness: | 0.18mm-2mm |

| Width: | 300mm-850mm |

| Color: | Clear / Transparent / Black / White / Customize Color |

| Shape&Weight: | Up to 150kg/Roll |

| Certificate: | SGS, ISO9001,ISO14001 |

| Temperature: | -30℃-120℃ |

Product Description

We all know that APET sheet is a kind of engineering plastic sheet, which can be used in many industries. In order to better guarantee its application performance, we need to pay special attention to the choice of raw materials when making APET coils. So what are the particularities in choosing raw materials?

In the general market, the raw materials for making engineering plastic sheets mainly include polyethylene, polypropylene, polyamide, polytetrafluoroethylene, ABS plastic, polyformaldehyde, polycarbonate, etc., but most of them will use polyethylene. This material has a molecular chain length of 10-20 times that of high-density polyethylene. The longer molecular chain (higher molecular weight) gives it higher toughness, abrasion resistance and stress crack resistance, because it is made of polyethylene A sort of.

Part of the reason for its popularity is that its APET sheet has good chemical properties. The chemical properties of APET sheet determine the best-selling situation of PET sheet. So what kind of chemical characteristics does APET sheet have? Let’s take a look at the chemical characteristics of APET sheet together! The melting point of APET sheet is about 265~280℃ and the density is about 265~280℃. It has excellent heat resistance and hunger resistance, good chemical stability, and high rigidity and toughness.

APET sheet has the characteristics of excellent resistance to most of the life and light industrial chemicals. The assembly has no moisture absorption and has good water vapor resistance and can be used for packaging purposes.

Our Advantages:

| Product Name | Bulk Conductive APET Plastic Sheet for Electronic Products |

| Material | 100% virgin PET raw material |

| Color | Any color |

| Certificate | SGS, ROHS, ISO, etc. |

| Grade | Medical grade, food grade and conductive grade |

| Width | 300~1400mm |

| Thickness | 0.15~3mm |

| Application | Mainly applied to the packaging of food, medicine, electronics, cosmetics&gifts. |

| Our Advantage | 1.Strict QC team,quality satisfaction rate meets 99% 2.More than 10 set advanced automated equipments,meet high end quality requirement 3.Free design service and fast sample lead time in 3 day |

| Sample Time | 1-3 days |

| Delivery Methods | Ocean shipping ,air transportation, express,land transportation |

| Payment Term | Credit card ,T/T,L/C,Western Union,Paypal |

| Transparency | Transparency,Semi-transparency,Opaque |

| Surface | Glossy/matt |

| Form | by roll or cut sheet form |

WHY CHOOSE USMore >>

Click to see workshop, equipment, certificated qualification and advantage strength of Pulixin(HK)- A professional PP PS PET sheet manufacturer

Not Trader But Factories

Up to 100% Virgin Material

Experience, Certification & Patent

High-standard Quality Inspection

Multiple Advanced Lines 7-12 Days Delivery

Safe Packing For International Transport

Product Application

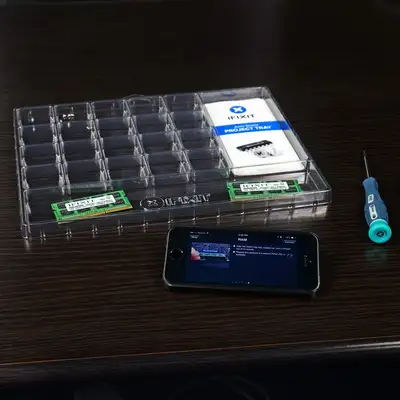

Conductive APET Plastic Sheet for Electronic Products normally has a wide range of useage like consumer product packaging, electronic tray, fresh food Crisper,cosmetic packaging, Medical device blister packaging.